Our services

Transformers tested, delivered, installed and monitored by our team

Tests

Before it leaves our workshop, every transformer undergoes a battery of tests to guarantee its compliance, among other things, with the basic international standard IEC 60076.

FROM LEFT TO RIGHT

Alexandre VIGNAL (Test technician)

Alexis DARNON (Test manager)

Gatien PRIVAT (Test technician)

Integrated

test platform

With its 3-strong team the test platform forms a veritable “control tower” in the workshop and is involved in the transformer manufacturing process from the very beginning. Our test technicians start by controlling the quality of the windings ensuring they are compliant with the design sheets provided by the design office, then they are involved at every stage of production through to the final acceptance of the transformers: the Factory Acceptance Tests, often carried out in the presence of the customer.

Overview

of the test platform

3 groups of tests

- These concern every transformer we make.

- They are carried out 100% in the factory.

OBJECTIVES:

- To ensure that the transformer’s characteristics are exactly those sold to the customer.

- To measure its performances (no-load losses, load losses, short-circuit voltage).

These concern the first transformer in a series of identical units. Optional tests including:

- Lightning impulse tests,

- Temperature rise tests,

- Noise level tests.

These are also optional tests, which may include: measurement of winding capacitance, frequency response analysis (SFRA), short-circuit withstand test, partial discharge test, dissolved gas analysis, measurement of dissipation factor (tan δ), etc.

A happy customer is a loyal customer!

celduc® transfo systematically invites its customers to the factory acceptance tests on their transformer. This provides an opportunity to discuss the project the transformer is for and allows us to explain the test procedures carried out and the results obtained. As the transformers manufactured in Sorbiers go into use on every continent and every ocean, it is not uncommon for our customers to make a long trip over to see us.

Our Libyan customers visiting Sorbiers

in November 2021

Logistics services

1. Loading the equipment

2. Shock data logger

3. Packing service

4. Choice of transport mode

1.

LOADING THE EQUIPMENT

Our logistics team loads your transformer onto the lorry and ensures that it is properly secured.

2.

SHOCK SENSOR AND LOGGER

• SHOCK SENSOR

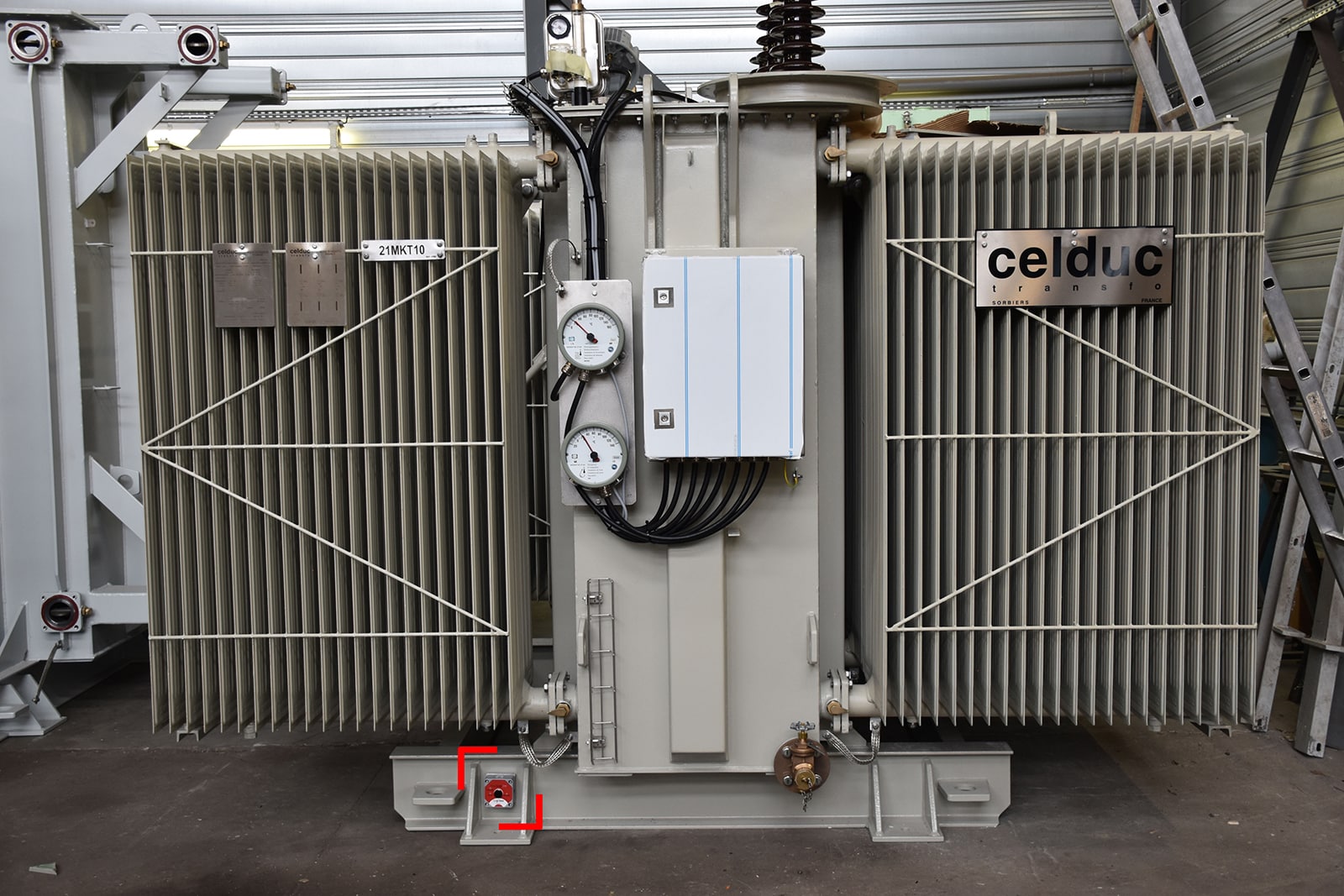

This is a mechanical device placed on the transformer tank that records any shocks suffered by transformer on arrival and estimates their severity.

• SHOCK DATA LOGGER

This is an electronic device placed on the tank which records the time and geographical location of the slightest shock event affecting the transformer during transport. It is essential that the device be returned to celduc® transfo so that we can consult the record of the shock events and print out the report.

The transformer can be fitted with either a shock sensor or a shock data logger.

3.

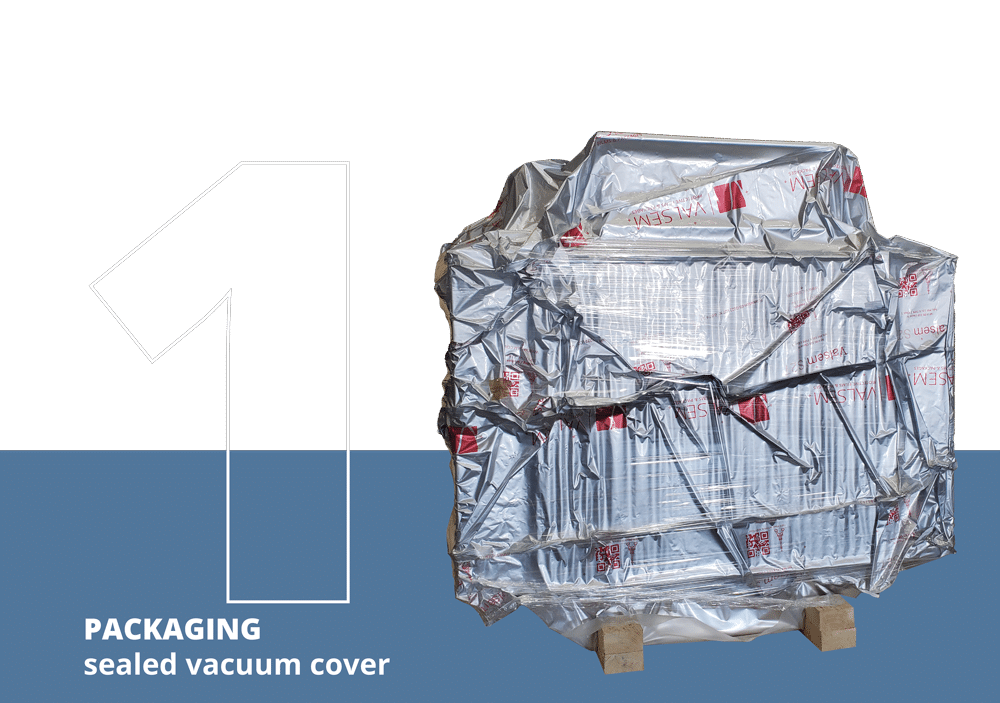

PACKING SERVICE

For transformers that are to be shipped by sea, celduc® transfo can provide SEI4c packing (wooden crate and watertight cover), which meets standard NIMP15, to protect your equipment against the elements.

4.

CHOICE OF TRANSPORT MODE

Our logistics team will give you the choice of collecting your transformer from our workshop (loaded and secured) or having us organise its transport to your chosen destination anywhere in the world. We work with a wide panel of freight forwarders so that we can organise transport of your transformer by road, sea or rail but also by air and according to the incoterm of your choice.

ABNORMAL LOAD

And if the transformer exceeds the standard size, that’s not a problem either…

We will get it to its destination using abnormal load arrangements.

After sales

Maintenance

Services on customer site

Spare parts

Manufacturer file

celduc® transfo's teams support you in monitoring your transformer over its lifetime in France and abroad

celduc® transfo‘s technical team can advise you on how to maintain and ensure optimum operation of your transformers for at least 30 years and, when necessary, will come out to your site anywhere in the world as soon as practicable.

celduc® transfo‘s technical team can advise you on how to maintain and ensure optimum operation of your transformers for at least 30 years and, when necessary, will come out to your site anywhere in the world as soon as practicable.

Installation, assembly, connection, acceptance, on-site testing, start-up assistance, staff training. Our teams can assist you through to the commissioning of the transformer if you wish.

celduc® transfo undertakes to provide spare parts for your transformer for 30 years.

celduc® transfo undertakes to provide spare parts for your transformer for 30 years.

Provision of a comprehensive manufacturer file with 3D plans, electrical diagrams of the windings and auxiliaries, test reports, instructions and manuals (transport, storage, operation), Safety Data Sheets and manuals or drawings for the accessories.

Provision of a comprehensive manufacturer file with 3D plans, electrical diagrams of the windings and auxiliaries, test reports, instructions and manuals (transport, storage, operation), Safety Data Sheets and manuals or drawings for the accessories.